EdgeBanding Technology

Looking to upgrade your EdgeBanding capabilities? Expect a solution that meets your manufacturing needs. Lekon’s advanced EdgeBanding systems provide cutting-edge technology for precision, durability, and seamless finishes. Perfect for woodworking manufacturers of any scale, our machines help you streamline production, enhance productivity, and achieve exceptional quality. Trust Lekon for innovative EdgeBanding solutions that deliver consistent performance and reliable results.

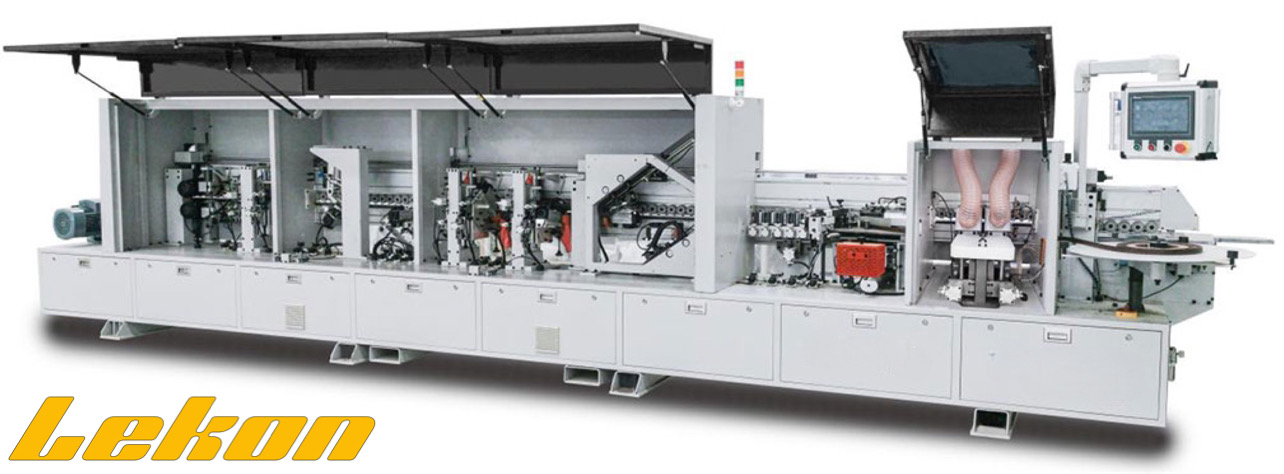

Discover Lekon’s EdgeBanding Technology

Looking to upgrade your EdgeBanding capabilities? Expect a solution that meets your manufacturing needs. Lekon’s advanced EdgeBanding systems provide cutting-edge technology for precision, durability, and seamless finishes. Perfect for woodworking manufacturers of any scale, our machines help you streamline production, enhance productivity, and achieve exceptional quality. Trust Lekon for innovative EdgeBanding solutions that deliver consistent performance and reliable results.

Advantages of EdgeBanding

- Enhanced Durability: EdgeBanding protects panel edges from moisture, wear, and impacts, extending the lifespan of furniture and cabinetry.

- Improved Aesthetics: It provides a clean, finished look that hides the exposed edges of materials, creating a seamless appearance.

- Cost-Effective: EdgeBanding offers a low-cost solution for finishing edges, especially compared to alternatives like solid wood.

- Customization: Available in a range of colors, textures, and finishes to match any design or material, adding versatility to manufacturing options.

- Ease of Maintenance: EdgeBanding simplifies cleaning and maintenance by sealing edges, preventing dirt and grime from settling in exposed areas.

Features of EdgeBanding Equipment

- Precision Glue Systems: Ensures even application and bonding for a seamless edge finish.

- Automatic Trimming & Buffing: Machines often feature trimming, shaping, and buffing tools for smooth, polished edges.

- Touchscreen Control Panels: Provides easy control and customization for different edge profiles and thicknesses.

- Fast and Consistent Processing: Designed for high-speed operations without sacrificing quality, allowing manufacturers to boost production rates.

- Flexible Material Compatibility: Capable of working with PVC, ABS, wood veneer, and other edge materials for a wide range of applications.

- High-Quality Feed Mechanism: Ensures smooth handling of panels, reducing the risk of misalignment or damage.

Applications of EdgeBanding

- Furniture Manufacturing: Essential for finishing cabinet doors, tabletops, and shelves, giving furniture a polished look.

- Cabinetry and Kitchen Components: EdgeBanding is widely used in cabinetry for sealing edges in humid environments like kitchens and bathrooms.

- Office Furniture Production: Applied to desks, shelves, and partitions, enhancing both durability and aesthetics in high-use spaces.

- Retail and Display Fixtures: Provides a clean, professional look for store displays, showcases, and fixtures that require durability.

- Interior Paneling: Ideal for wall panels and other interior decor elements, ensuring longevity and a refined finish.

EdgeBanding solutions from Lekon support these applications with precision-engineered equipment that meets high-quality standards across diverse woodworking projects.