Edge Banding

The single-sided edge banding machine is expertly engineered to apply edge materials to rectangular workpieces, utilizing a variety of edge materials such as PVC, ABS, and Acrylic. This machine excels in both longitudinal and transverse processing modes, ensuring a high-quality finish and precise application. Ideal for professional woodworking shops, it delivers consistent performance, enhancing productivity and achieving superior results.

Advantages

The main functions:

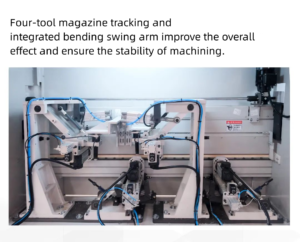

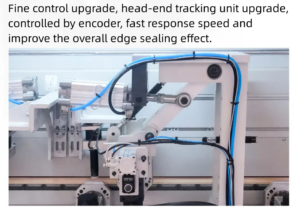

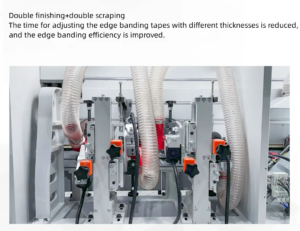

Pre-spraying → pre-milling → preheating lamp 1→ gluing 1 (without cleaning the glue pot) → single-channel tape feeding 1→ six-wheel pressing 1→ preheating lamp 2→ gluing 2 (with quick sol) → single-channel tape feeding 2→ six-wheel pressing 2→ three-motor trimming → fine repair 1→ fine repair 2→ four-knife tracking → edge scraping 1 (anti-adjustable knife for directional wire blowing) → edge scraping 2→ flat scraping→ Spray Clean Agent→ Buffing 1&2

Closer Look

Buffing unit

Buffing unit

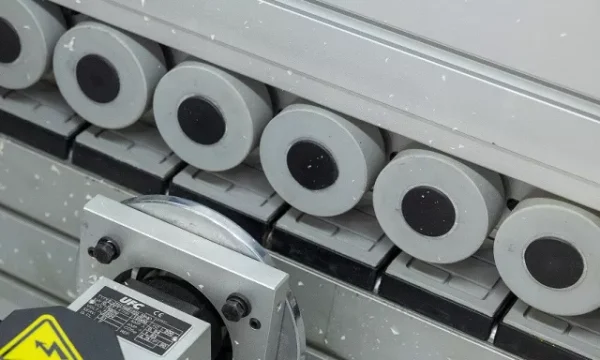

Double V-belt Top Pressure System (Optional)

Double V-belt Top Pressure System (Optional)

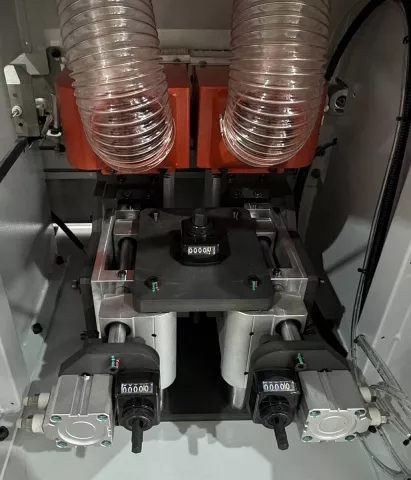

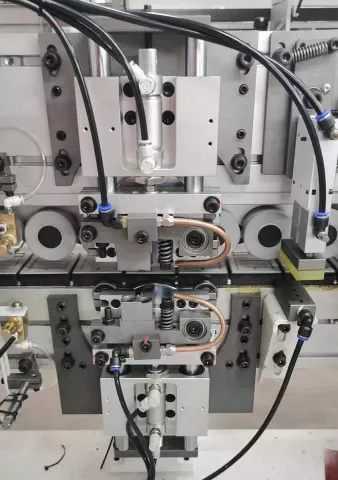

Gluing unit -Two glue reservoirs

Gluing unit -Two glue reservoirs

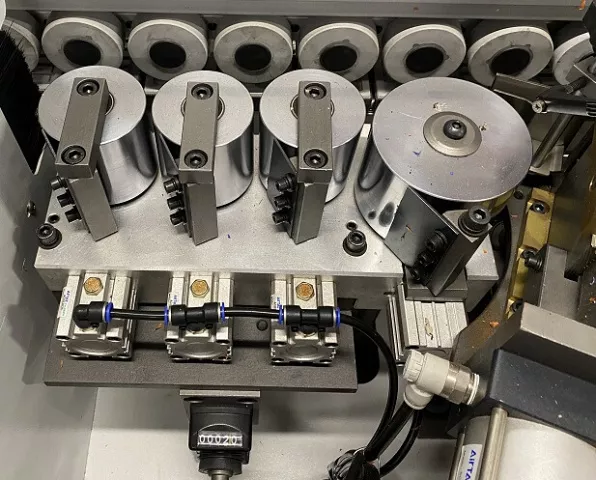

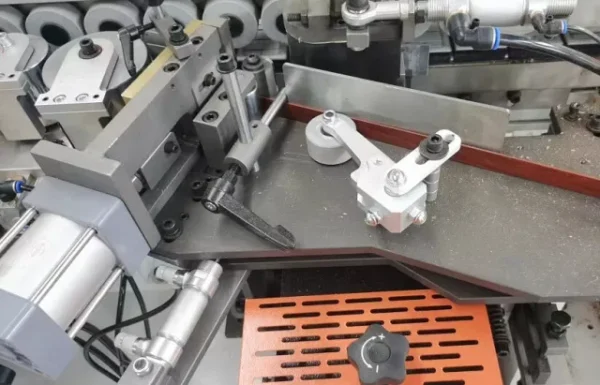

High-speed corner trimming

High-speed corner trimming

Off-cut&Flat Scrapping

Off-cut&Flat Scrapping

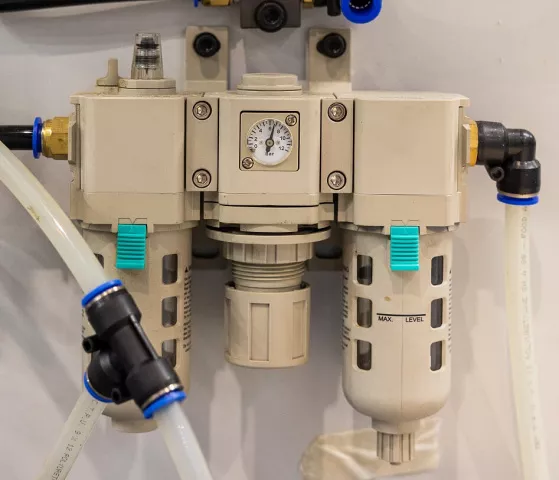

Different Glue Application Systems (Optional)

Different Glue Application Systems (Optional)

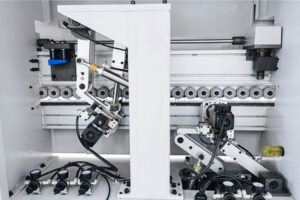

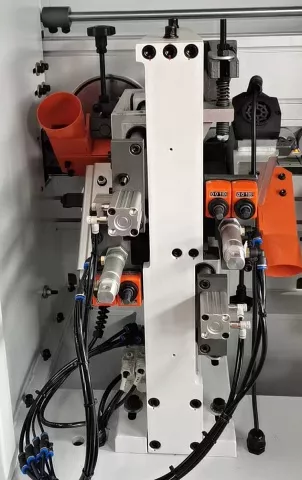

Pre-milling unit

Pre-milling unit

R Scraping

R Scraping

Customized solution to fit your unique requirements

Customized solution to fit your unique requirements

Reviews

There are no reviews yet.