Edge Banding

The single-sided edge banding machine is expertly engineered to apply edge materials to rectangular workpieces, utilizing a variety of edge materials such as PVC, ABS, and Acrylic. This machine excels in both longitudinal and transverse processing modes, ensuring a high-quality finish and precise application. Ideal for professional woodworking shops, it delivers consistent performance, enhancing productivity and achieving superior results.

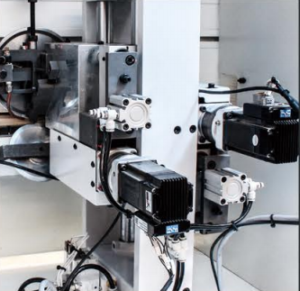

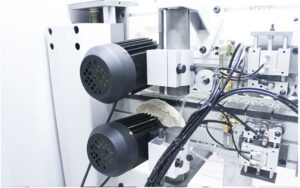

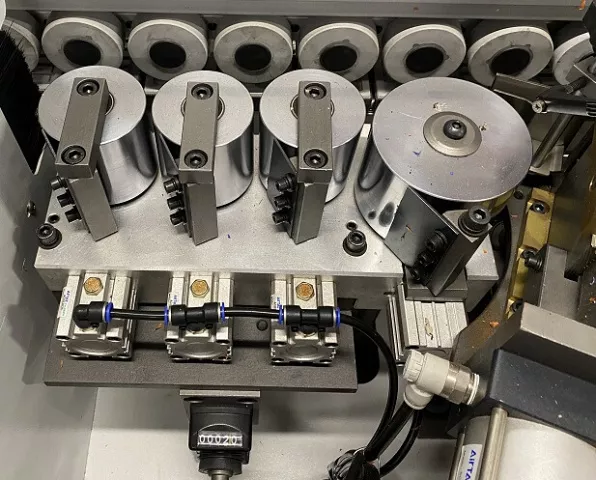

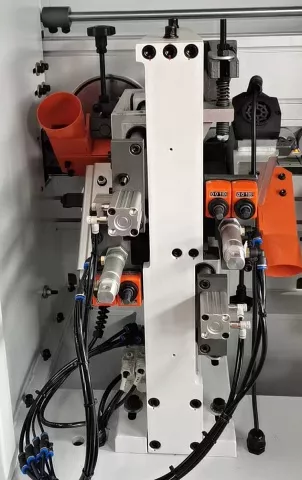

Heavy-duty trimming unit.

Heavy-duty trimming unit.

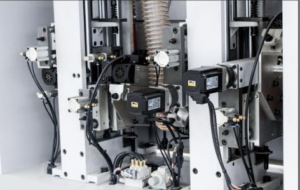

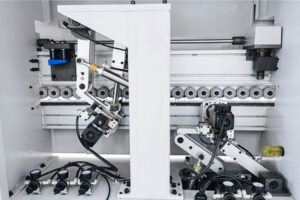

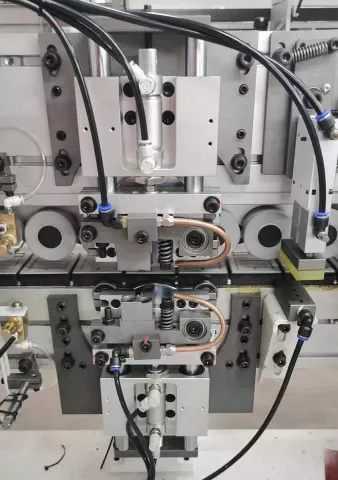

Servo control unit. Accurate adjustment, reduce standby time, increase productivity.

Servo control unit. Accurate adjustment, reduce standby time, increase productivity.

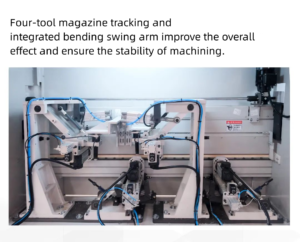

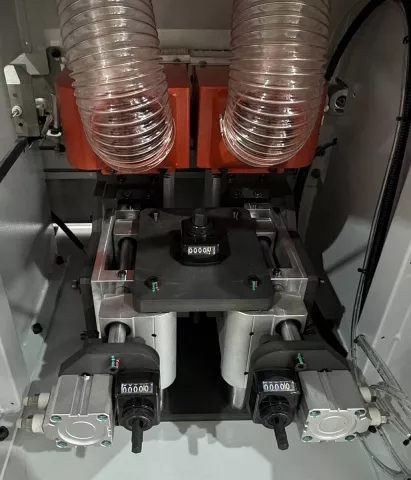

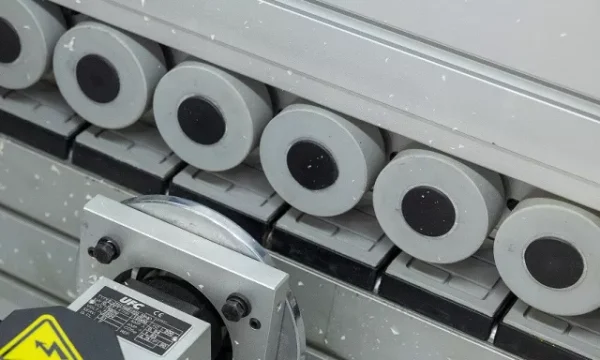

Servo tape magazine. Multiple wheel magazine automatically changes edge with servo motor.

Servo tape magazine. Multiple wheel magazine automatically changes edge with servo motor.

The process is both accurate and swift. 4/6/12 tape magazines optional Conveyor line.

The process is both accurate and swift. 4/6/12 tape magazines optional Conveyor line.

Conveyor line.

Conveyor line.

Automatic conveyor line.

Automatic conveyor line.

Advantages

The main functions for :

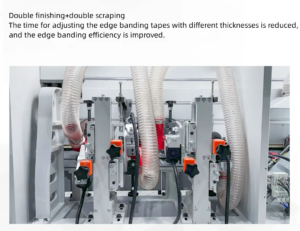

Double v-belt top pressure → spray release agent →per milling →servo driven multiple wheel tape magazine1→pre melt1→servo driven pressing 1 →servo driven multiple wheel tape magazine2→pre malt2 →servo driven pressing 2 →double rail end trimming→ heavy-duty pneumatic rough trimming→heavy-duty servo fine trimming→ servo high speed corner trimming →heavy-duty servo scraping →off-cut→flat scraping→spray clean agent →electric buffing1→electric buffing2

Closer Look

Buffing unit

Buffing unit

Double V-belt Top Pressure System (Optional)

Double V-belt Top Pressure System (Optional)

Gluing unit -Two glue reservoirs

Gluing unit -Two glue reservoirs

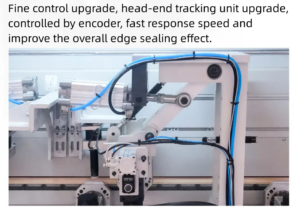

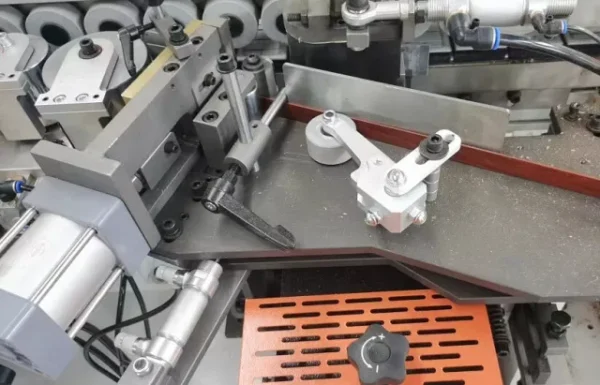

High-speed corner trimming

High-speed corner trimming

Off-cut&Flat Scrapping

Off-cut&Flat Scrapping

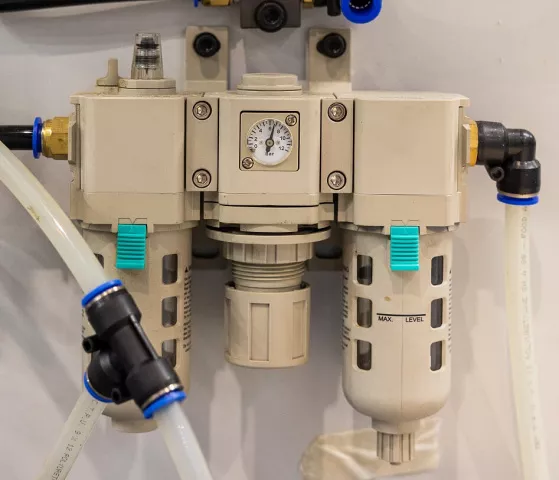

Different Glue Application Systems (Optional)

Different Glue Application Systems (Optional)

Pre-milling unit

Pre-milling unit

R Scraping

R Scraping

Customized solution to fit your unique requirements

Customized solution to fit your unique requirements

Reviews

There are no reviews yet.