⬇️ Click below to access the related file ⬇️

Edge Banding

A Compact Edgebander offers several advantages, especially for small to mid-sized woodworking shops and businesses looking for efficiency without taking up too much space. Here are the key benefits:

Advantages

The main functions:

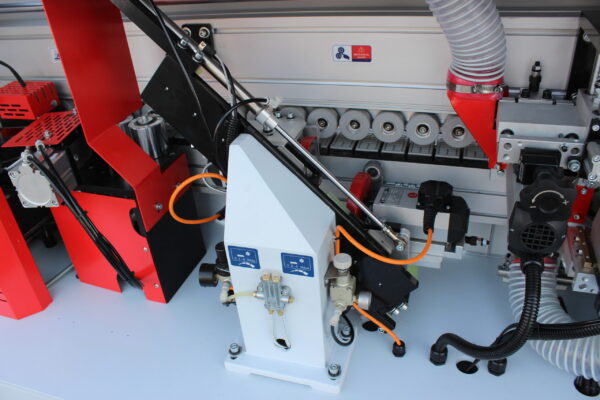

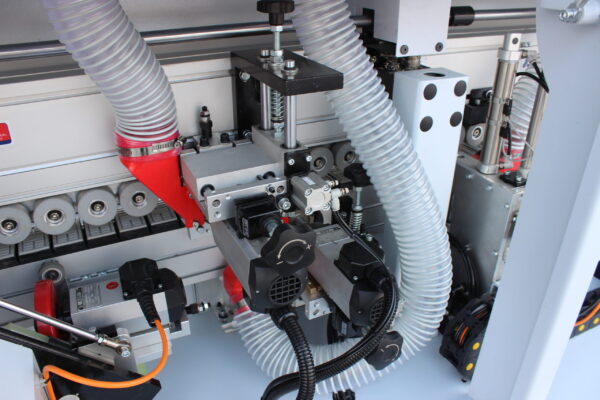

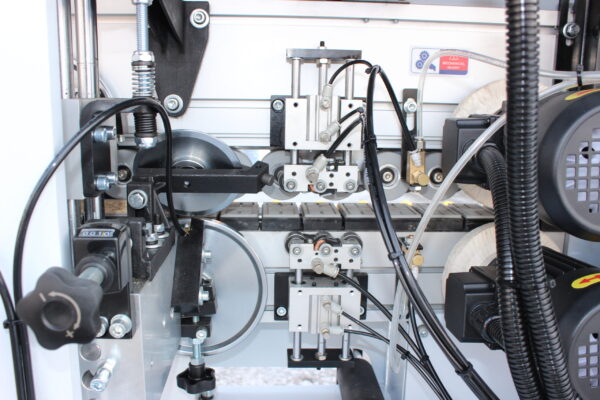

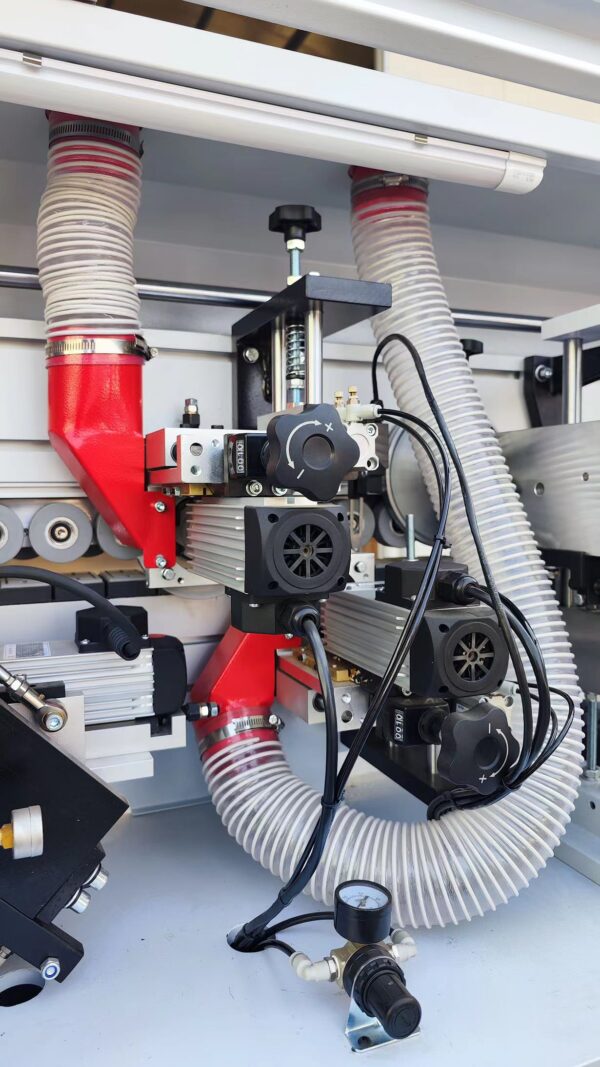

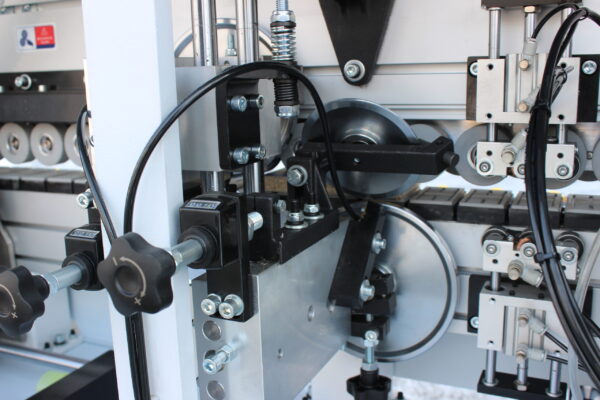

Pre-Milling → Gluing (Removable GluePod Station) → Single-Channel Tape Feeding → Three-wheel pressing → End Trimming → Fine Trimming → Corner Rounding → Round Scraping → Buffing

1. Space-Saving Design

- Ideal for small workshops or businesses with limited floor space.

- Can be easily moved or repositioned if needed.

2. Cost-Effective

- Lower initial investment compared to larger industrial edgebanders.

- Reduced energy consumption leads to lower operating costs.

3. Ease of Use & Quick Setup

- Designed for simple operation, making it easier for beginners and small teams.

- Faster setup times mean increased productivity.

4. Versatile Performance

- Handles a variety of edge banding materials (PVC, ABS, wood veneer, etc.).

- Suitable for different panel sizes and thicknesses.

5. Reduced Waste & Material Efficiency

- Precision trimming and gluing minimize material waste.

- Helps maintain a clean and professional edge finish.

6. Low Maintenance

- Fewer complex components make maintenance easier and less expensive.

- Many models feature automatic glue pot cleaning to reduce downtime.

7. Mobility & Flexibility

- Some models are portable or easy to relocate based on shop needs.

- Great for on-site jobs or small production runs.

Reviews

There are no reviews yet.